The race to build climate-resilient coral reefs

Novel restoration methods can speed up the recovery of threatened corals – but for a lasting impact, they need to be backed by action to stop ocean warming, reports Chris Iovenko.

A new ally may help speed up the race to restore devastated coral reefs in Australia: robots, combined with mass-manufacturing techniques. Around the world, scientists are also working on other methods to help reefs recover faster and on a larger scale than before. But as corals face existential threats, including a steady increase in the intensity and duration of marine heat waves, experts warn that these solutions need to go hand in hand with action on global warming if they are to bring lasting improvements.

Taryn Foster is a coral scientist based in Western Australia and chief executive of Coral Maker, which produces small coral skeletons onto which nursery grown coral is attached. She was spurred into action by the mass bleaching she witnessed while doing research for her doctoral thesis on climate impacts on coral reefs.

“I was studying these big reefs and saw how quickly a bleaching event devastates a reef system,” says Foster. “In the space of a few weeks during one of the bleaching events, we saw around 90% coral mortality. And I was reconsidering whether or not I wanted to continue to write scientific research papers, or whether I wanted to get more involved in practical, more solutions-based work.”

The ocean absorbs 90% of the heat caused by human-driven climate change. Warming oceans are a huge problem for coral reefs as they require temperatures to stay within the range of 79-84F (26.1-28.8C) to remain healthy, grow, and reproduce. Current predictions estimate that 99% of coral could succumb to marine heatwaves by the 2030s if global temperatures continue to rise at the current rate.

This would have dramatic consequences not just for corals, but for the wider reef ecosystem. Although coral reefs only occupy 0.1% of the seafloor, 25% of all named marine species live in reef systems and an estimated one billion people benefit directly or indirectly from coral reefs. Coral ecosystems face a host of threats ranging from increasing ocean acidification to a rise in coral diseases but the steady and alarming increase in ocean surface temperatures poses the most ubiquitous and ominous problem.

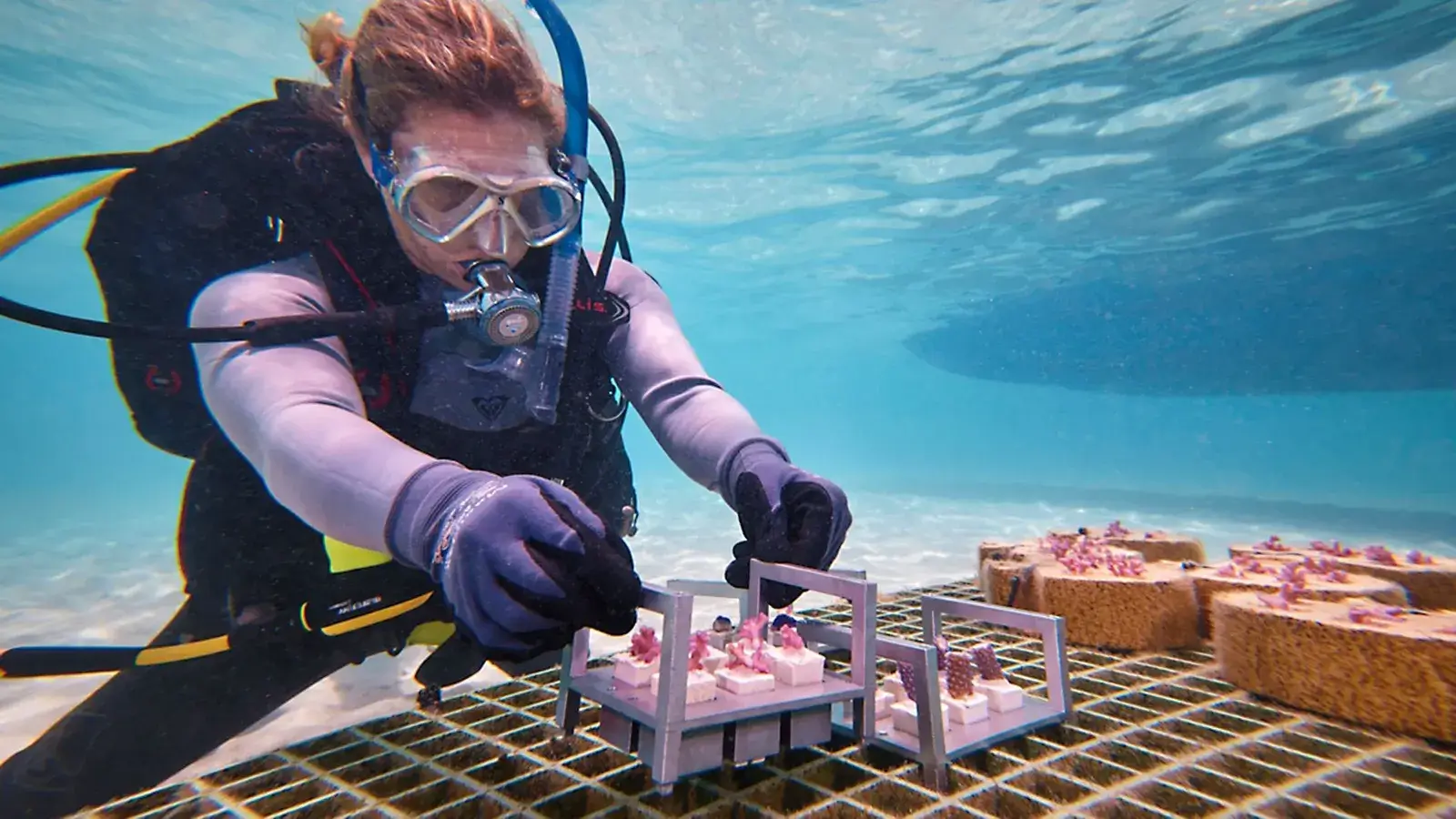

Coral restoration typically involves transplanting nursery-grown coral onto the damaged reef by hand using individual divers, a very time consuming and arduous process that can be expensive and hard to do on a large scale. Foster decided that a new approach was needed to scale up coral planting, incorporating lessons from her family’s manufacturing business, such as automation and mass production.

“I was thinking we can apply some of these technologies to coral reef restoration,” says Foster. “There’s lots of parts of the process that are just pick and place, repetitive type tasks which are ideally suited to robotic automation.”

She partnered with software company Autodesk, which helped her implement automation and artificial intelligence into a process that could manufacture skeletons for coral. Foster says using artificial intelligence to program and run the robotic side of the operation allows for greater flexibily and accuracy.

“Unlike standard pre-programmed robotic systems, artificial intelligence is able to respond to the variability in coral morphology and adjust robotic movements accordingly,” says Foster.

To create corals for planting, robots work alongside humans, attaching nursery-grown coral fragments to mass-produced coral skeletons on an assembly line. The material used for the coral skeletons is rock or cement; currently Coral Maker uses recycled construction rubble.

Foster says current restoration programmes can generally restore about 2.5 acres (1 hectare) of coral reef in a year, but that once Coral Maker is fully operational it could restore around 250 acres (100 hectares) a year.

A race is also underway in the US, to save the bleached corals of the Flordia Keys Reef Tract. Florida’s coral reef system, which is the third largest in the world, is under severe threat. Now, a novel approach is boosting the survival chances of two of its primary reef-building coral species, both of which are endangered: the pale brown, pointed-antler-like staghorn (Acropora cervicornis) and the flattened-antler-like elkhorn (Acropora palmata). Both the staghorn and the elkhorn have been devastated by disease and climate change, and have seen a 97% decline in their population since the 1970s. The Coral Restoration Foundation (CRF), the world’s largest reef restoration organisation, was formed in 2005 in response to this population crash.

CRF operates coral nurseries in the ocean that grow juvenile coral, which are then transplanted to reef restoration sites in an effort to stave off the extinction of coral species and restore balance to the reef ecosystems. The corals are grown on floating, anchored trees made from polyvinyl chloride (PVC) with fibreglass branches onto which coral fragments are attached with thin plastic lines. This structure allows them to grow particularly fast, says Phanor Montoya-Maya, CRF’s restoration programme manager. This is because the suspended corals are surrounded by light and waterborne nutrition and are more protected from storms and other disturbances than they would be if they were anchored to the sea floor. According to Montoya-Maya, the corals are “reef-ready” in six to nine months.

CRF’s Tavernier Coral Tree Nursery in the Florida Keys covers 1.5 acres (6,070 sq m) of ocean floor, contains more than 500 coral trees, and is capable of producing 40,000 reef-ready corals every year, the organisation says.

![Progress on Climate Conference [?] Progress on Climate Conference](https://eyesonsuriname.com/storage/2023/12/Progress-on-Climate-Conference-150x150.webp)